Stop Running Your Shop. Start Running Your Business.

We build manufacturing operations systems that replace the ERP/MES/QMS sprawl with something that actually fits your process.

Custom-built systems for shop owners who are buried in operations and engineering teams drowning in handoff chaos across CNC, laser, fab/weld, assembly, and additive.

Buy Back Your Time

Systems that run without you

No Spreadsheet Chaos

Real systems, real data management

Built for You

Custom systems that fit your shop

See Your Shop. From Anywhere.

Finally take that vacation you've been dreaming of. Check in from the beach, the mountains, or your back porch. Your shop runs on desktop, tablet, and mobile. You can step away without losing control.

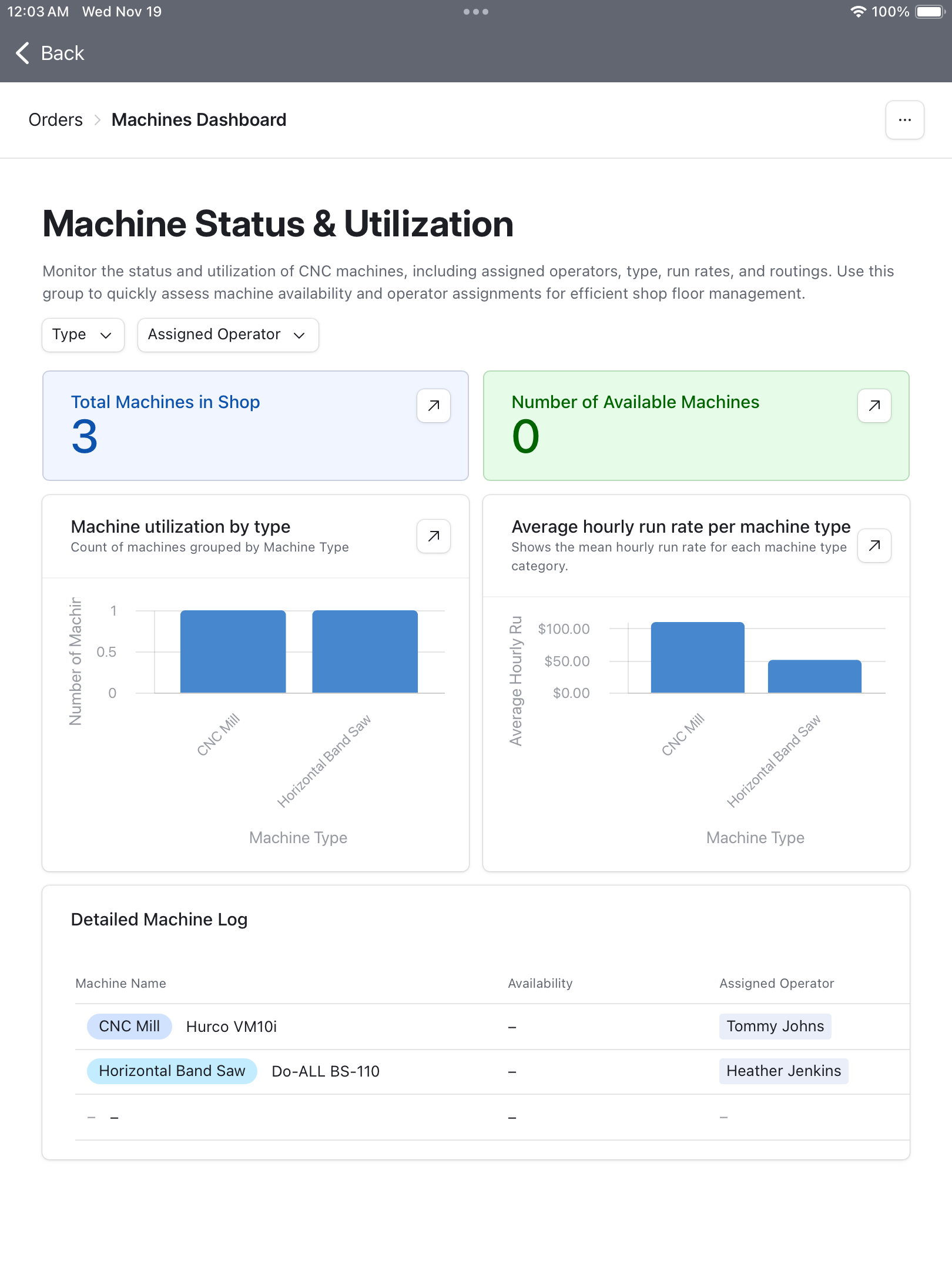

Monitor from Anywhere

Check machine status, job progress, and inventory levels from your phone: whether you're at lunch or on vacation.

Your Team Gets Answers

Shop floor, office, or field. Everyone has real-time access to the information they need without calling you.

Built for Real Work

Not clunky, desktop-only software. These systems work on tablets for the shop floor and phones for owners on the go.

This is how you buy back your time: systems that work without you being there.

For shop owners buried in operations and engineering teams drowning in handoff chaos

Custom operations systems for job shops, contract manufacturers, custom builders, and engineering firms

For Shop Owners: Stop Answering the Same Questions

Every question pulls you away from growing the business. Your team needs visibility with systems that answer questions automatically.

Your shop needs systems that work without constant input. Systems that give you your time back.

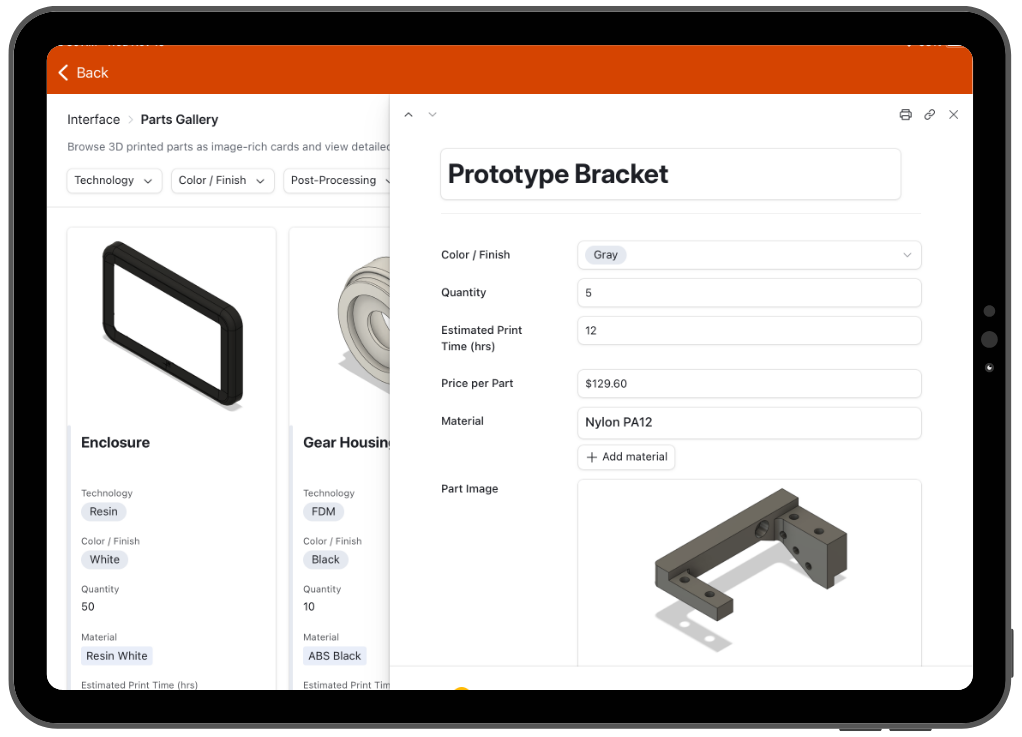

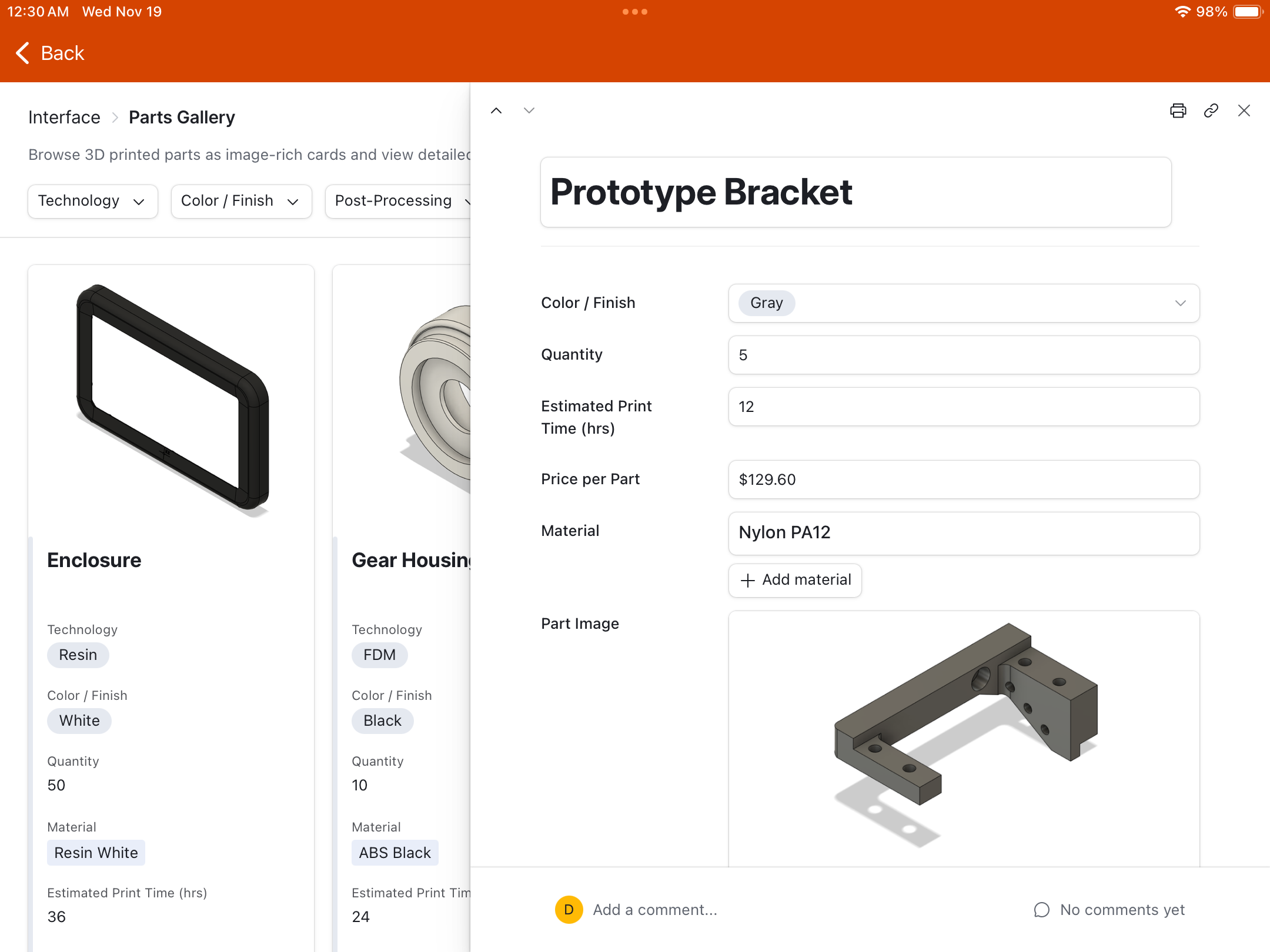

For Engineering: Stop Re-Sending Files and Tracking Revisions Manually

Every project involves chasing down the latest CAD file, clarifying which revision is current, and answering "where's the updated spec?" for the third time.

Engineering release management shouldn't be project management madness. Your handoff process needs structure before it reaches the shop floor.

We build release systems that centralize files, track revisions automatically, and integrate 3D visualization with specifications so manufacturing always has the right version.

Systems That Run Your Shop Without You

We build custom operations systems that handle the work you're tired of doing manually. From training your team to tracking production, we automate the chaos so you can focus on growing the business.

Buy Back Your Time

Systems that run without you

No Spreadsheet Chaos

Real systems, real data management

Built for You

Custom systems that fit your shop

Off-the-shelf templates coming soon, but custom-built systems are what actually solve your problems.

For Shop Owners: Stop Answering the Same Questions Every Day

Your team shouldn't need to call or text you to know what's happening in the shop. They need real-time access to machine status, job progress, and inventory without you being the middleman.

Check machine status, job progress, and inventory levels from your phone, whether you're at lunch or on vacation.

For Engineering: Stop Re-Sending Files and Tracking Revisions Manually

Every project involves chasing down the latest CAD file, clarifying which revision is current, and answering "where's the updated spec?" for the third time.

We build release systems that centralize files, track revisions automatically, and integrate 3D visualization with specifications so manufacturing always has the right version.

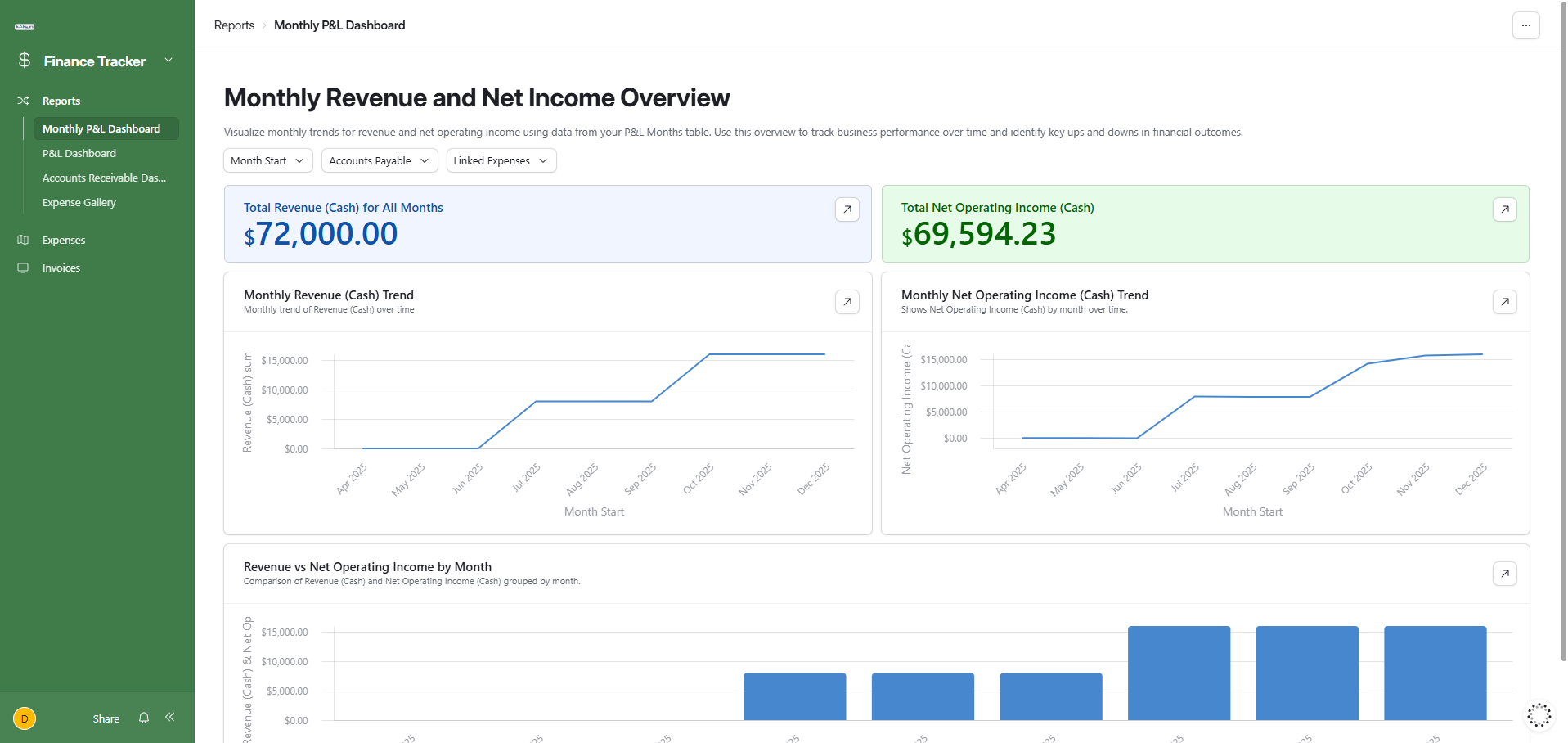

Stop Hunting for Job Status and Financial Performance

You're digging through spreadsheets to answer "how much did we make last month?" or "what jobs are eating our margin?" You don't have clear visibility into what's making money and what's not.

Financial dashboards shouldn't require an accounting degree or hours of manual work. You need instant visibility into revenue, margin, and job profitability.

We build P&L tracking systems that show monthly trends, operating income, and job-level profitability so you can make decisions based on real data, not guesses.

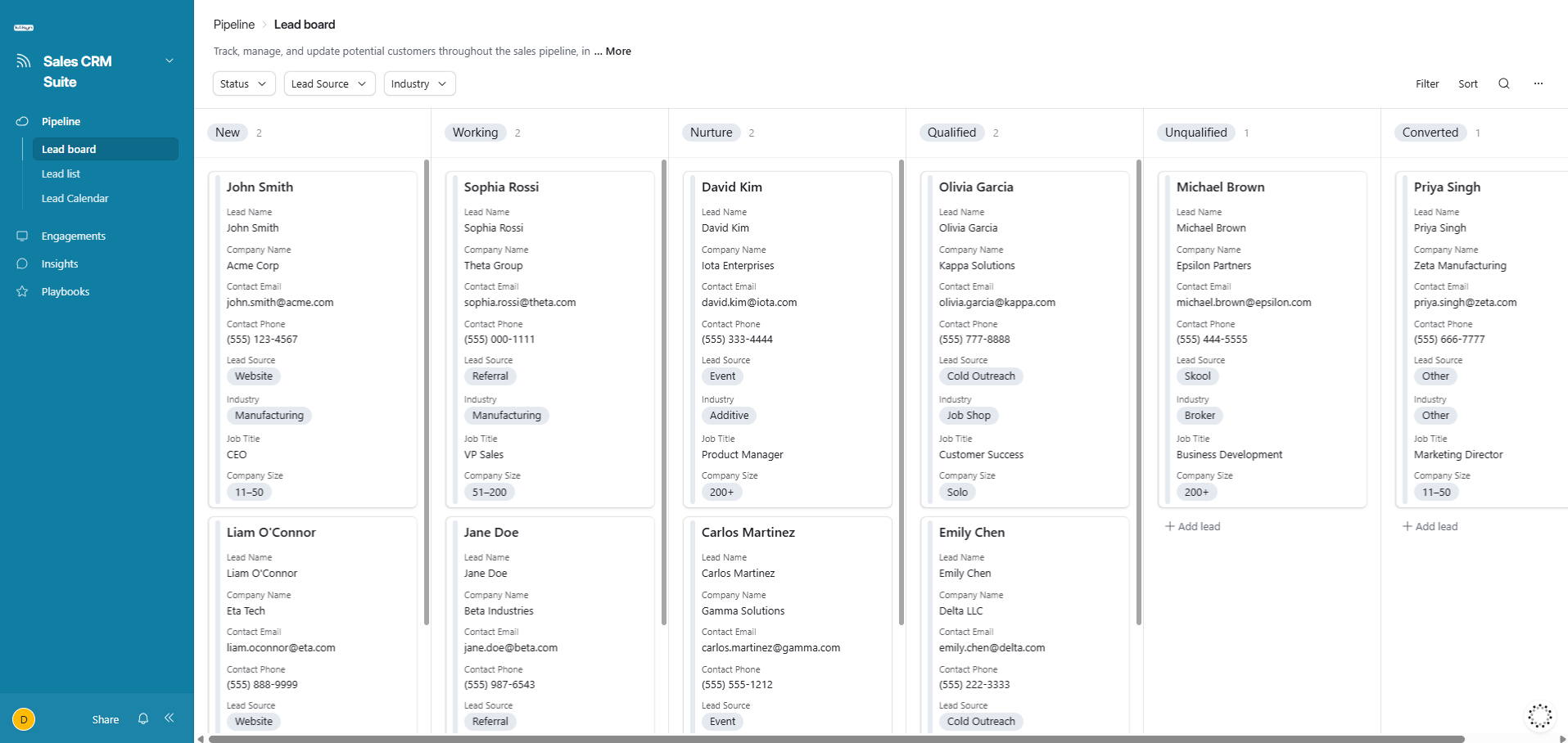

Stop Losing Track of Customer Conversations and Opportunities

Leads fall through the cracks because you're juggling emails, phone calls, and sticky notes. You can't remember who you talked to last week or what stage each prospect is in.

Your sales process shouldn't live in your head or scattered across tools. You need a clear pipeline that shows every opportunity and where it stands.

We build lead tracking systems that organize your pipeline, capture contact details, and show deal progression so you never lose an opportunity again.

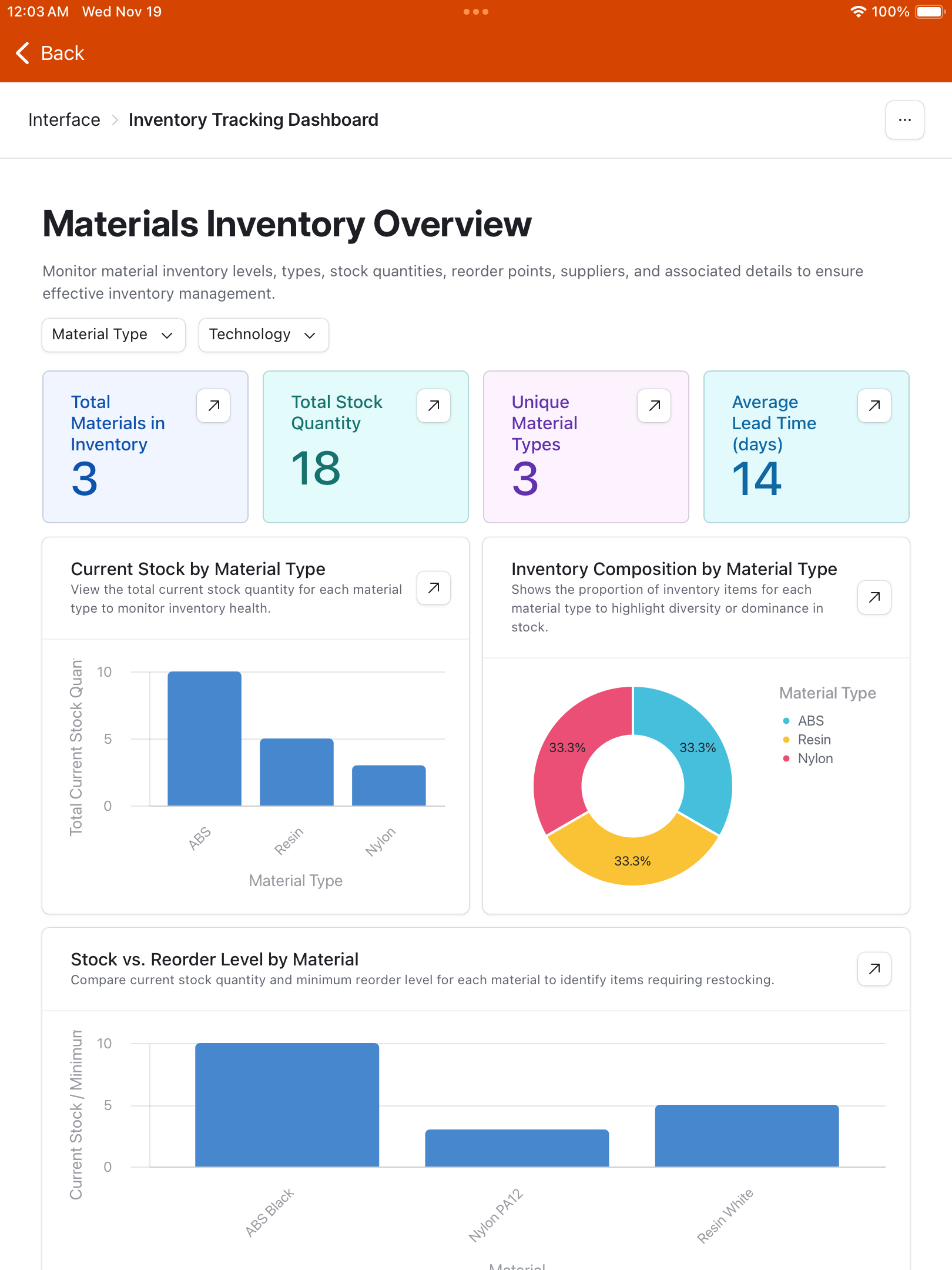

Stop Running Out of Materials Mid-Job

You discover you're out of stock when production stops. Reordering is reactive, not proactive. You don't have visibility into what's on hand, what's running low, or when to reorder.

Materials management shouldn't be a guessing game. You need automated alerts and clear visibility into inventory levels before you run out.

We build inventory tracking systems with reorder point alerts, stock quantity monitoring, and material type classification so you're always ahead of the curve.

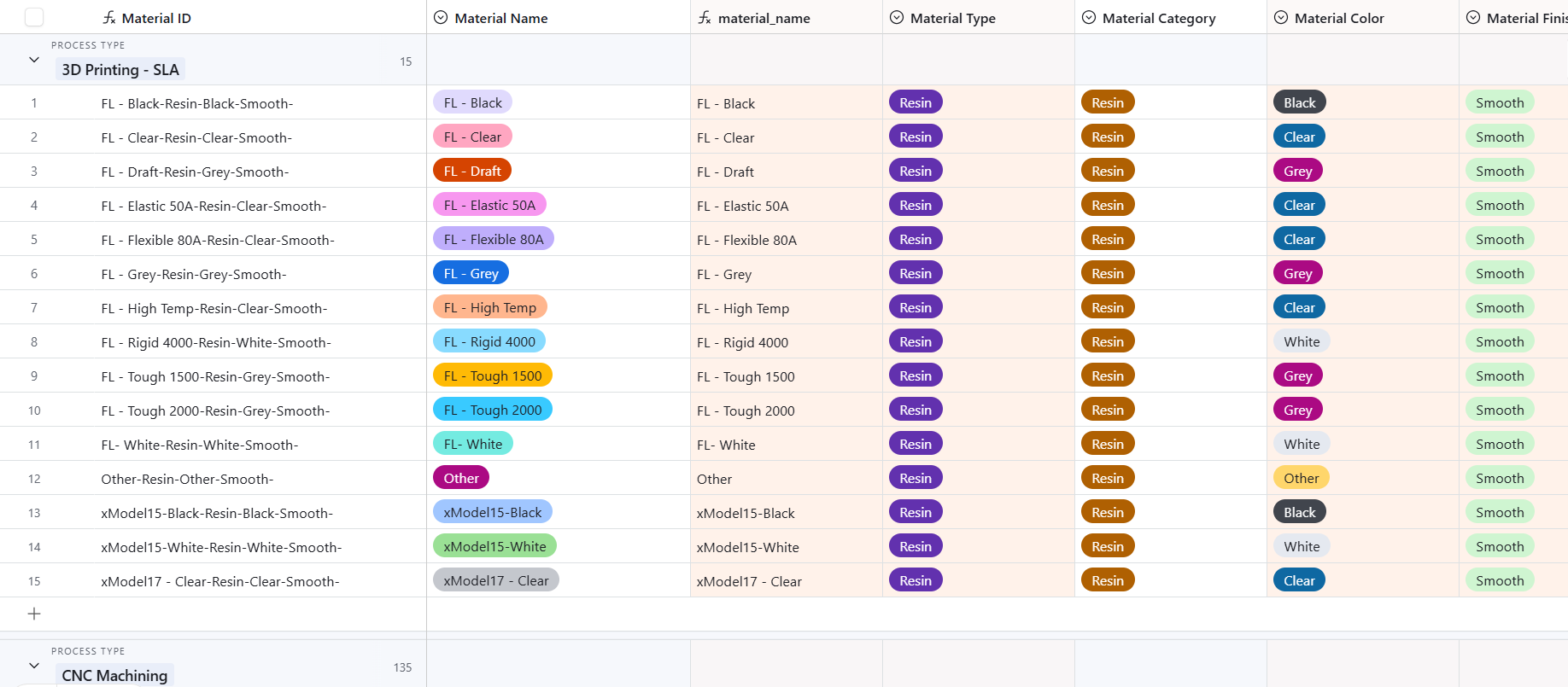

Detailed Material Tracking with Real Data Management

Not just dashboards. Production-ready data systems with structured materials tracking, color-coded badges, process type grouping, and complete specifications for every item in inventory.

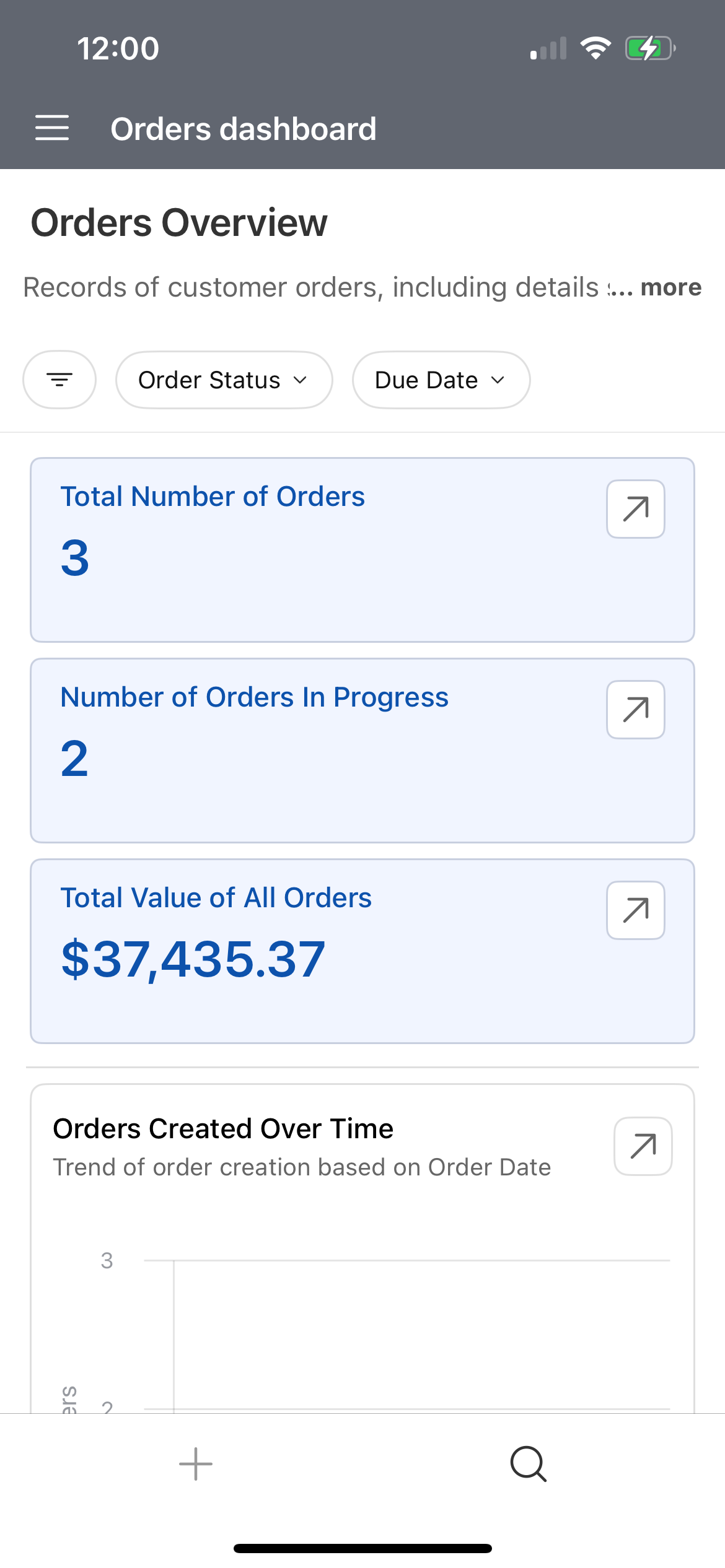

Stop Losing Track of Active Jobs and Customer Orders

You're juggling multiple customer orders with no clear view of what's in progress, what's on hold, or what needs attention. The shop floor asks you for priorities, and you're digging through notes to figure it out.

Order tracking shouldn't require memory or detective work. You need instant visibility into every active job and its status.

We build order management systems that show total orders, in-progress jobs, total value, and trends so you always know what's on your plate.

Stop Fighting Your Systems. Start Using Them.

Whether you're buried in operations or drowning in handoff chaos, we build systems that take the burden off. Custom-built for your shop, your team, your process.